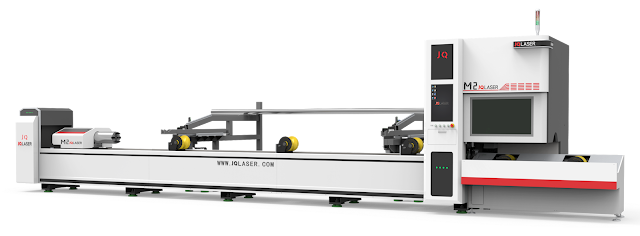

M series tube laser cutting machine, 6meters, 8meters tube cutting length, diameter 20-230mm, semi loader and auto loader for option.

FLT 6022M M1 new design tube laser cutting machine, faster, more efficient

https://youtu.be/6-2p1bathsQ

FLT 6022M M2 new design servo follow-up tube laser cutting machine, faster, more efficient

https://youtu.be/ztIuhnS93QE

FLT 6022M M3 new design automatical loading system tube laser cutting machine with servo follow up, faster, more efficient

https://youtu.be/-0ui_D-ItEI

Advantages of Laser Tube Cutting

JQ LASER Tube cutter comes with a lot of advantages. Let's take a look at a few.

Flexibility

Laser tube cutting can handle a lot of different sizes and shapes of tubes. From less than an inch all the way up to 9 inches, cut the diameter of the tube you need. Rectangular tubes can also be cut up to 9 inches across.

Length is no issue either. Standard tubing of 24 feet is easily taken care of.

A quarter of an inch of carbon steel is no match for laser tube cutting. Machines can also cut through stainless steel up to 0.25 inches. And on titanium, laser tube cutting gets through 0.04 inches with no problems either.

Use laser tube cutting on tubes with round, rectangular, or irregular profiles.

Shape, size, and thickness are no problems. The variety that laser tube cutting can handle shows the broad flexibility these machines can deal with.

Materials

Laser tube cutting works on a wide range of materials. Choose this method for carbon steel, aluminum, stainless steel, and titanium.

If you need to cut reflective material, you should opt for a fiber laser rather than a CO2 cutter.

Efficiency

Because laser tube cutters are so precise and flexible, they are also extremely efficient. Tubes cut with these machines do not need any extra processing after the cut. The cuts are clean and precise, so there are no leftover materials to remove.

Cutting to length and doing complex designs are done with one machine. There are no additional tools needed. This means you don't have to change out pieces or parts, so your workflow is improved.

By using one piece of raw metal for all parts, laser tube cutters reduce the waste. This reduces the cost of your project.

Parts cut by a laser tube cutter will fit together easily and precisely. That means the secondary construction is simple and efficient as well.

Precision

The precision of cutting from a laser tube cutter means no secondary operation is needed. The parts are ready to use or assemble once they come off the cutter.

Cost

The efficiency and precision of laser tube cutters mean producing even complex parts is simple and automated. The automation reduces manual labor and improves time to completion. Your production line will be less costly when using a laser tube cutter.

Choose a Laser Tube Cutter

As you can see, for all your tube cutting needs, a laser tube cutter is the way to go. With so many options in what you can cut and how you can cut it, these tools offer you unparalleled flexibility.

The efficiencies you gain from automation and precision allow you to maximize your production workflow. You don't need secondary work done to clean up the cuts and joins. And your complex designs are easy for a laser tube cutter to handle, too.

When you're looking to find a laser tube cutting fabricator, we've got you covered. Our team of experts has years of experience working with these machines and customers like you. We offer quality assurance so that you can be assured you're work will get done on time and to the standards you expect.

Contact us today to learn more about our work or to get a quote. We'll be happy to assist you and find the best laser tube cutting solutions for your needs.

Jinan JinQiang Laser CNC Equipment Co., Ltd

Jinan JinQiang Laser CNC Equipment Co., LtdCell/Whatsapp: 0086 1555 000 2101

Email: jqlaser31@jqlaser.com

Website: www.jqlaser.com

Facebook: https://www.facebook.com/jqfancy

Youtube video: www.youtube.com/user/FancyWang1